Why is surface abrasion of concrete surfaces at transfer stations and industrial floors so important?

The constant scraping of your floor's surface is, perhaps, the most incessant of the challenges you need to protect against. Day after day, the uppermost surface, the near surface wear zone of your floor, is being beaten and worn away, almost invisibly—until it's too late. Once the wear surface is gone, all that's left is loosely bound aggregate and cement paste. Now, vulnerable to impact and contaminants, the unprotected floor surface faces rapid surface deterioration, costly and time-consuming replacement, and the very real risk of having to halt operations.

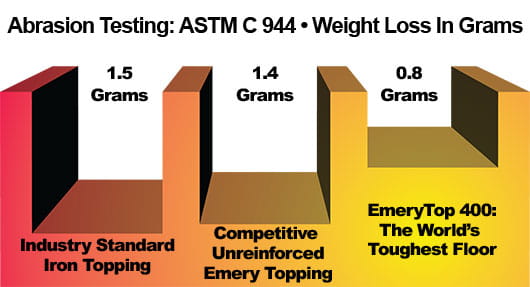

How well does L&M™ EMERYTOP 400 Protect Against Abrasion?

In an independent test, L&M™ EMERYTOP 400™ was compared to a competitive, unreinforced emery aggregate topping and to a popular, industry standard iron aggregate topping. The products were tested to determine relative abrasion resistance in accordance with the familiar ASTM C 944 test, utilizing rotating cutter wheels to simulate rapid abrasion. Under identical laboratory conditions, EMERYTOP 400 proved to be nearly twice as resistant to abrasion as the other leading brands.

What is important to understand about impact damage?

Constant blows and repetitive strikes from heavy machinery threaten to crack even the thickest transfer station and industrial concrete floors. L&M™ EMERYTOP 400™ is the first line of defense.

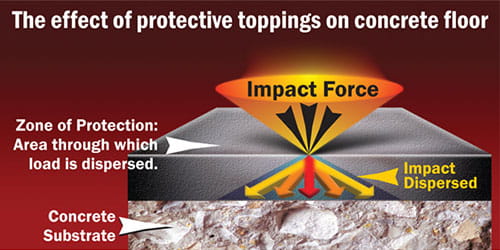

Industrial toppings must not only protect the near-surface wear zone from abrasion but also protect the underlying concrete from impact and point loads. In order to protect industrial floors from impact and point loads the protective material must produce a zone of protection.

The pattern of travel takes on the shape of a right circular cone, with the base being the area over which the load is dispersed at a given depth into the substrate material and the upper point being the initial point of contact.

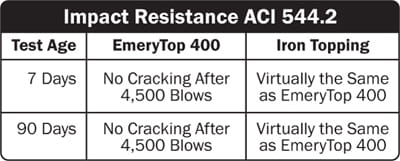

How does does impact resistance of EMERYTOP 400 compare to an iron aggregate topping?

How does chemical attack affect a concrete surface?

In most high strength toppings, the cement paste is usually the first component to submit to chemical attack and begin to fail. After a relatively short period of time, the cement paste of either a concrete floor or of a cement based topping will begin to weaken and erode, losing its grip on the high strength aggregates and creating a weakened condition called micropitting. While initially difficult to detect, given the dirty environment that exists in most industrial and solid waste facility floors, micropitting becomes readily apparent as large areas of the floor surface deteriorate off the concrete substrate.

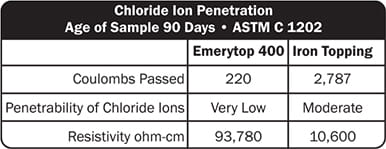

How does EMERYTOP 400 protect against the effects of chemical attack?

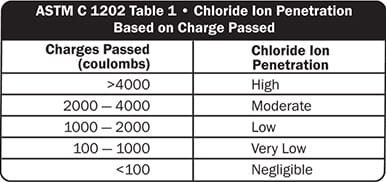

EMERYTOP 400 floors are uniquely protected against chemical attack through chemical strengthening and densifying of the cement paste. No other product can boast of the dramatic benefits that this feature provides the owner of an EMERYTOP 400 floor. This internal sealing and strengthening of the topping greatly slows the rate of chemical penetration, resulting in a dramatic increase of the floor's life cycle. Independent tests show that EMERYTOP 400 is resistant to contaminant penetration in accordance with ASTM C 1202, and shows a significantly lower corrosion rate (when measured in coulombs) when compared to high strength iron toppings.

How does EMERYTOP 400 save costs?

EMERYTOP 400 saves facility owners significant material cost, lasts twice as long as iron toppings and is easy to apply:

1. Better Yield and Coverage Rate - To properly protect a floor, normally about an inch of topping is specified. Let's compare material weights for similar protection:

- Iron toppings: 18.7 lbs per sq. ft. at 1" depth. (224 lbs/cu. ft.)

- EMERYTOP 400: Just 14 lbs per sq. ft. at 1" depth. (168 lbs/cu. ft.)

2. Double the Service Life - Abrasion testing indicates that EMERYTOP 400 has approximately twice the service life as that of an iron topping. Chemical testing shows that it more effectively slows the rate of chemical penetration when compared with iron-topped floors. Impact testing proves that EMERYTOP 400 is at least as impact resistant as an iron topping.

3. Ease of Application - Iron toppings are prone to delamination caused by placement difficulties and its inherent drying shrinkage. Iron toppings are required to be anchored to hardened concrete with short nails (anchor pins) and must be glued to the concrete substrate using an epoxy bonding agent.

In contrast, whether EMERYTOP 400 is being installed over freshly placed or hardened concrete, it utilizes a low cost, easy to follow bonding procedure which ensures proper and natural, stress-free bonding of the topping to the base slab. Installing contractors also find the placement of this flowable product easy. This means savings for the contractor and the owner.

Where do I find more information?

Visit the EMERYTOP 400 product page and data sheet (DS-177) for more information. If you have additional questions or want to discuss an upcoming project, contact us!