Stucco per piastrelle che resiste al tempo, all'usura e alle intemperie.

Da oltre 65 anni, i nostri esperti sviluppano soluzioni innovative per la malta per risolvere problemi come la fessurazione, la consistenza del colore e la resistenza chimica, il tutto rimanendo al passo con le tendenze del design e le tavolozze di colori.

Le malte epossidiche, le fughe premiscelate e le fughe cementizie LATICRETE offrono tutte le caratteristiche e i vantaggi ricercati dai professionisti dell'edilizia, dai progettisti e dai proprietari di case.

-

Categoria di prodotto

-

Categoria di prodotto

Garanzie

x -

Categoria di prodotto

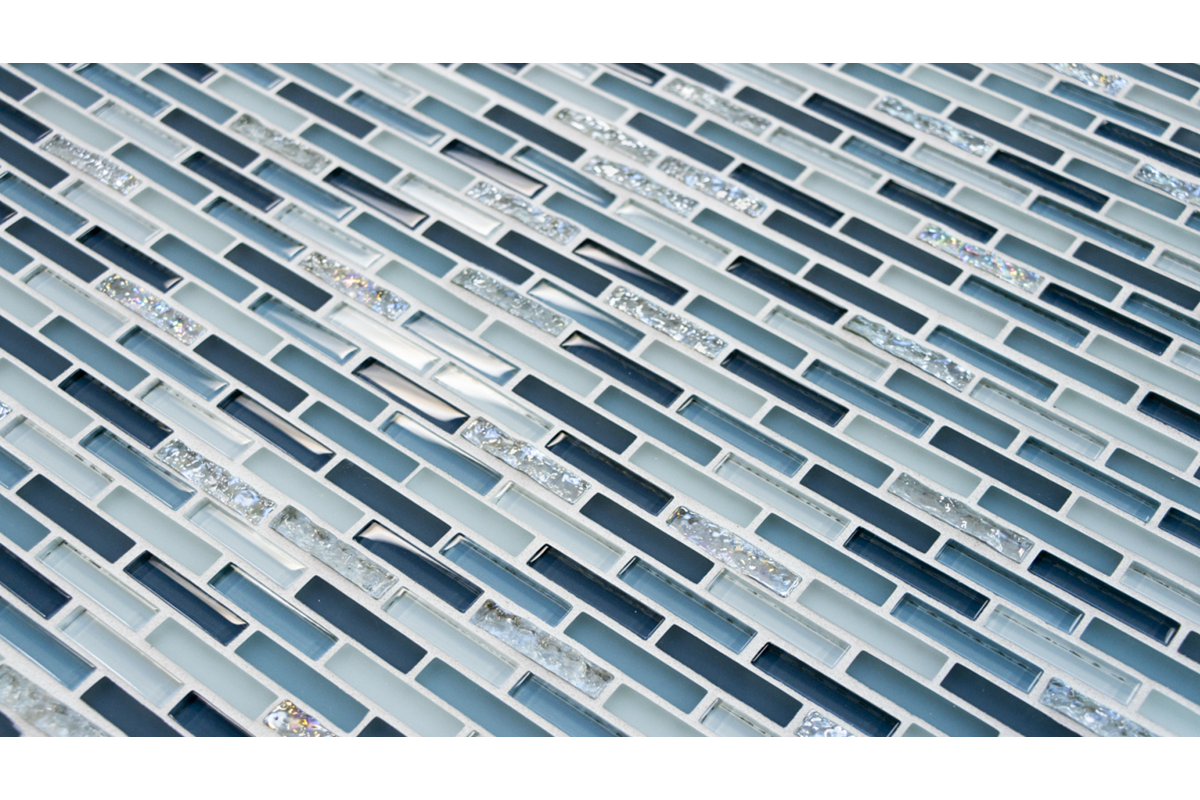

Completa il tuo look personalizzato!

Con il programma di corrispondenza dei colori personalizzati ANYCOLOR™, non ci sono limiti alle tue scelte di colore. Crea look unici nel loro genere utilizzando una combinazione di colori, un design o una tavolozza di marchi unici, oppure abbina un design esistente per ristrutturazioni e aggiunte che si integrano perfettamente in qualsiasi progetto.

Un colore per ogni progetto!

Usa il nostro selettore di colori per vedere l'ampia varietà di colori, mastici, sigillanti, profili e finiture e malte adesive a presa sottile offerti da LATICRETE.

Richiedi un campione

Hai bisogno di un campione per il tuo prossimo progetto? Esplora la nostra vasta libreria di campioni di fughe e profili.

Tecnologia di dispersione dell'acqua (WDT)

L'innovativa tecnologia impiegata nelle nostre malte cementizie PERMACOLOR® e PERMACOLOR Select migliora la dispersione dell'acqua durante tutto il processo di miscelazione. WDT aumenta la resistenza e la densità dei nostri prodotti per fughe, ottenendo fughe fino al 20% più resistenti* e fino al 30% in più di resistenza alle macchie*. Per ottenere prestazioni di stuccatura più efficaci e superiori con queste formulazioni, è fondamentale seguire con precisione le istruzioni di miscelazione.

*Rispetto alle formulazioni originali PERMACOLOR Grout e PERMACOLOR Select Grout.

Porta il tuo design al limite™ con i nostri profili e finiture.

Scegli tra una gamma completa di oltre 4.000 profili e finiture adatti a pavimenti, pareti, scale, insenature, giunti di dilatazione e altro ancora. Disponibile in un'ampia gamma di materiali e in una moltitudine di forme e dimensioni in una vasta selezione di finiture e colori, compresi i colori di malta LATICRETE più popolari e le opzioni di colore personalizzate, è facile trovare il prodotto giusto per il lavoro.

Resources

FAQs - Common Questions We Get Asked

- What's New in Mortar and Grout Products?

Advancements in pre-mixed grout saves you both time and resources. Choose from SPECTRALOCK 1 or READY-TO-USE grout options with endless grout color choices! Learn more about the innovations made in our blog on mortar and grout products. - How do I Pick the Best Grout for my Project?

Grout, when properly installed, will enhance the final appearance and performance of any tile, paver, stone, or brick installation. LATICRETE Technical Services Department offers this LATICRETE Grout Guide (TDS 400) to ensure that the project specifier is given enough information to make the best possible decision about the selection, installation and maintenance of grout. - How do you Care for Cement Grout?

Regular and routine maintenance is required to maintain the long term beauty of the grout, and, wiping up spills quickly and thoroughly will help minimize the possibility of staining. Learn how to maintain your grout in our blog, "Cement Grout Care and Maintenance". - What Factors Affect the Final Cement Grout Color?

Color variation is inherent with any cement based grout. There are many variables which can affect the final color of the grout. Some of these variables include uneven hydration of the cement, varying density and porosity of the tile or stone, type of substrate, over-glazed tile edges, self-spacing tile lugs, varying amounts of water used for grout mixing, excessive or varying amounts of water used during grout clean-up, job site conditions, mortar high in the joint, lighting, and different manufacturer’s “dye lots” when multiple units of grout are installed. Learn more in our TDS 174. - Is Epoxy Grout Easy to Use?

Grouting with epoxy is no longer confined to restaurants or industrial facilities. With new technology and availability, the average homeowner is now demanding a stain-resistant epoxy grouted tile installation. Learn quick tips on how to use SPECTRALOCK® PRO Premium or SPECTRALOCK PRO Grout* in TDS 191. - How do I Remove Epoxy Grout Haze?

LATICRETE produces easy to use epoxy based grouts. When LATAPOXY® and LATICRETE Grouts are used in accordance with installation and clean-up methods they will enhance your tile project by creating long lasting durability and beauty. However, we know sometimes haze happens. Review TDS 198 to follow these steps to remove epoxy grout haze. - How can I Grout Narrow Vertical Joints with SPECTRALOCK PRO Grout and SPECTRALOCK PRO Premium Grout?

Follow the steps outlined in TDS 149 when grouting with these epoxy grouts in narrow, vertical grout joints. - What is the Proper Method for Epoxy Grout Joint Removal?

There are several different methods including: mechanical, chemical or use of a heat gun. Learn how to use these grout removal methods by following our TDS 111. - How do I Re-Grout Floor Joints in a Commercial Kitchen or Industrial Application?

Degradation or deterioration of an epoxy grout can occur when the circumstances are right or when the wrong epoxy grout is used in areas subject to extreme conditions. Degradation or deterioration of portland cement based grouts is a more common occurrence in harsh commercial and industrial applications or areas exposed to chemicals. Follow TDS 144 to learn the tools needed, options to remove deteriorating grout and how to re-grout using SPECTRALOCK® 2000 IG. - What is the Best Grout Solution for Commercial Kitchens (Back of the House) and Industrial Applications?

The best defense against harsh chemicals, the use of no-rinse cleaners, extreme conditions or exposure to bacterial attack is to use high performance epoxy grouts designed for use in these demanding environments. SPECTRALOCK 2000 IG, in #22 Midnight Black, is the best product to use for optimal performance in these harsh environments. Learn more in TDS 258.

Our grout products exceed the toughest commercial criteria, providing worry-free installations!