Système de revêtement industriel

Un système de revêtement industriel de haute performance conçu pour gérer des environnements abusifs qui subissent des niveaux élevés de chocs thermiques, d’impacts et d’abrasion.

Offrant un fini mat, il est disponible dans un choix de 6 couleurs. Les zones d’utilisation communes comprennent les cuisines commerciales et les installations de fabrication.

-

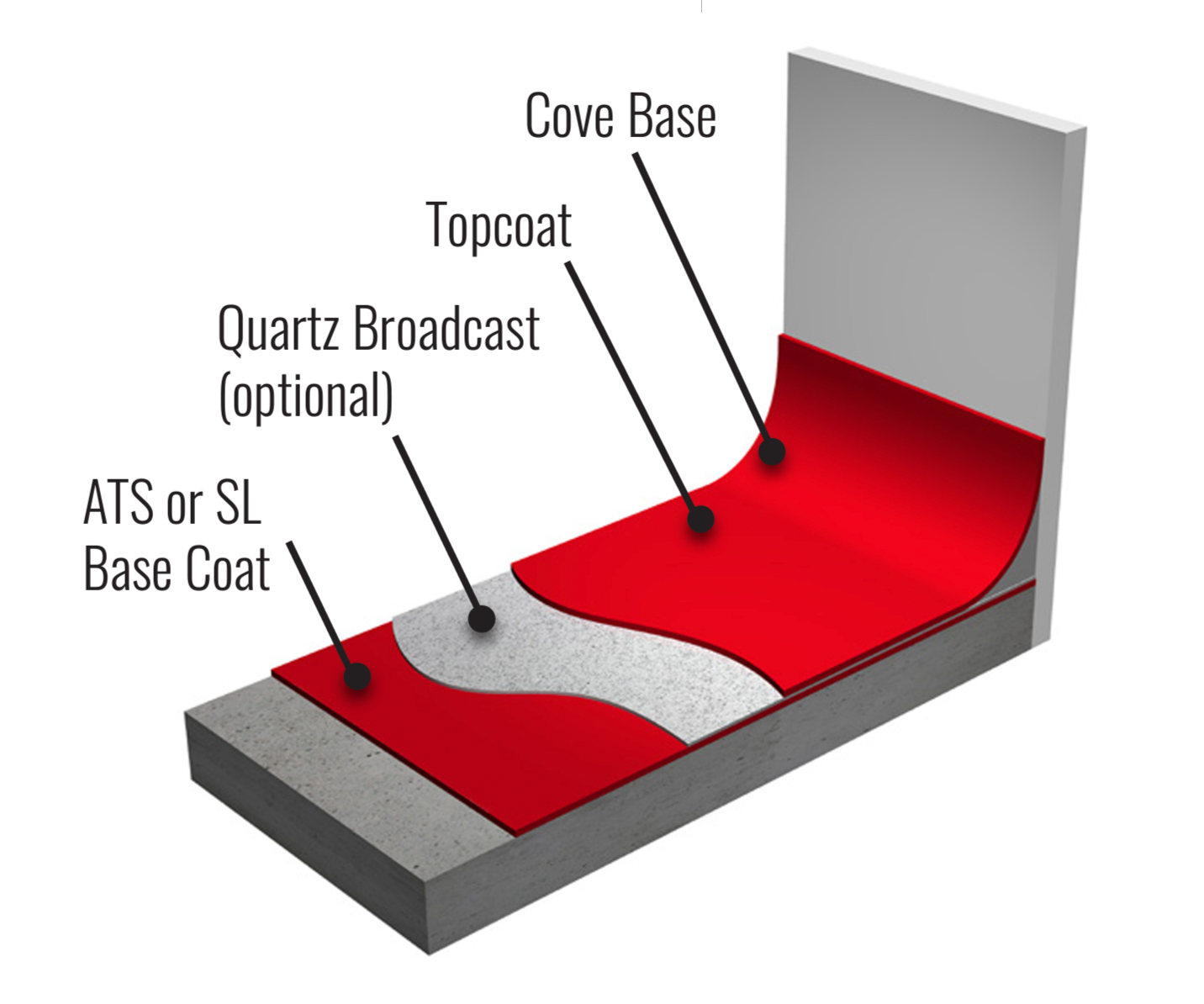

SPARTACOTE® Urethane Cement ATS

For high to medium duty environments

Surface Preparation: Mechanically profile to CSP-4 to CSP-5

Number of Coats: 1

Overall Thickness (DFT): 1/8” (neat) or ¼” (with broadcast)System Build

- Base Coat: SPARTACOTE Urethane Cement ATS

- Broadcast: SPARTACOTE Blended Quartz (Optional)

- Top Coat: SPARTACOTE Urethane Cement top coat (Optional)

Features

- For high to medium duty environments

- Resists thermal shock

- Excellent abrasion and impact resistance

- FDA/USDA compliant

-

SPARTACOTE Urethane Cement SL

For medium duty environments

Surface Preparation: Mechanically profile to CSP-3 to CSP-5

Number of Coats: 1

Overall Thickness: 1/8” (neat) or 3/16” (with broadcast)System Build

-

Base Coat: SPARTACOTE Urethane Cement SL

- Broadcast: SPARTACOTE Blended Quartz (Optional)

- Top Coat: SPARTACOTE Urethane Cement Top Coat (Optional)

Features

- For medium duty environments

- Self-leveling

- Resists thermal shock

- Excellent abrasion and impact resistance

- FDA/USDA compliant

-

Base Coat: SPARTACOTE Urethane Cement SL

-

SPARTACOTE Urethane Top Coat

For light duty environments

Surface Preparation: Mechanically profile to CSP-3 to CSP-5

Number of Coats: 2

Overall Thickness: 1/16”System Build

-

Base Coat: SPARTACOTE Urethane Cement Top Coat

- Broadcast: SPARTACOTE Blended Quartz (Optional)

- Top Coat: SPARTACOTE Urethane Cement Top Coat

Features

- For light duty environments

- Excellent abrasion and impact resistance

- FDA/USDA compliant

-

Base Coat: SPARTACOTE Urethane Cement Top Coat